Home » Drill Solutions » Industry News » Best rock drilling tools for hard rock – 2026 latest guide!

Best rock drilling tools for hard rock – 2026 latest guide!

Drilling through hard rock—such as granite, basalt, or quartz-rich sandstone—presents unique challenges for mining, construction, and infrastructure projects.

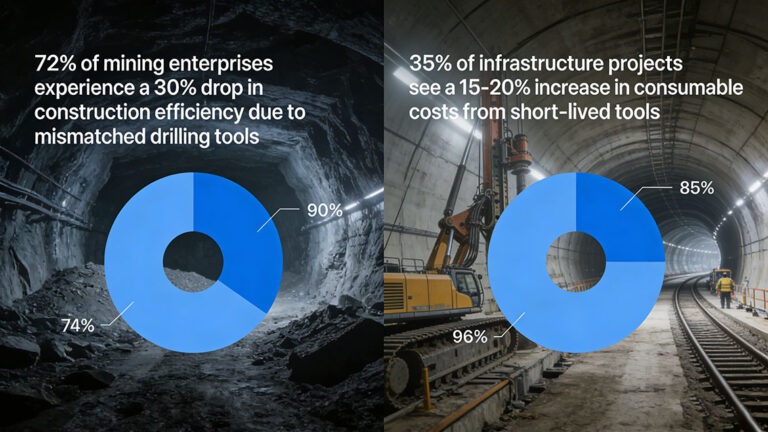

Industry research shows that 72% of mining enterprises experience a 30% drop in efficiency due to mismatched Rock drilling tools, while 35% of infrastructure projects face a 15-20% increase in consumable costs due to short-lived tools.

Main Requirements for Hard Rock Drilling Tools

Hard rock formations, typically with a hardness coefficient greater than 10 or compressive strength above 180 MPa, impose significant demands on tool strength, impact resistance, and wear resistance. The following four factors are key considerations for rock drilling in hard rock formations:

- Material Strength: The impact and abrasion of hard rock formations can be withstood by high-grade alloy steel, tungsten carbide, and polycrystalline diamond composite (PDC) bits.

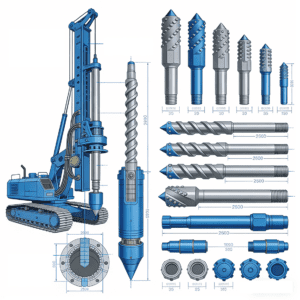

- Selecting Drill Bits:Tapered bits,threaded bits, and other such constructions are appropriate for this high-hardness rock since they allow for higher rotational speeds and extended tool life.

- Compatibility: The Rock drilling tools must be compatible with the rig types (top hammer or down-the-hole hammers) and meet project requirements such as hole diameter and drilling depth.

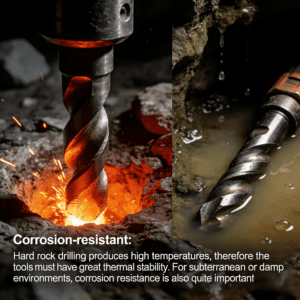

- Corrosion-resistant:Hard rock drilling produces high temperatures, therefore the tools must have great thermal stability. For subterranean or damp environments, corrosion resistance is also quite important.

Best Rock Drilling Equipment for Hard Rock in 2026

Following hard rock applications across mining, construction, and infrastructure projects, the following rock drilling tools stand out based on field performance, industry reviews, and technical innovation.

1、Down-the-hole Drilling Tools:DTH hammers and bits are ideal for deep, large-diameter hole solutions. They are perfect for deep foundation piles in hard rock, water well drilling, and blast hole drilling.

Why They Excel: Delivering peak impact energy with little waste, the hammer action directly behind the bit at the hole’s bottom is a major benefit in tough, dense formations.

1、Down-the-hole Drilling Tools:DTH hammers and bits are ideal for deep, large-diameter hole solutions. They are perfect for deep foundation piles in hard rock, water well drilling, and blast hole drilling.

Why They Excel: Delivering peak impact energy with little waste, the hammer action directly behind the bit at the hole’s bottom is a major benefit in tough, dense formations.

Conclusion

Selecting the most suitable rock drilling tools for hard rock is crucial for cost savings. Investing in KSQ rock drilling tools, specifically designed for hard rock, ensures effective profitability. Whether it’s rugged down-the-hole hammers or top hammer drilling tools, the right equipment can significantly enhance your operations.

Want to learn more about hard rock drilling tools? Contact KSQ Drill today for personalized recommendations tailored to your specific rock conditions and drilling objectives.