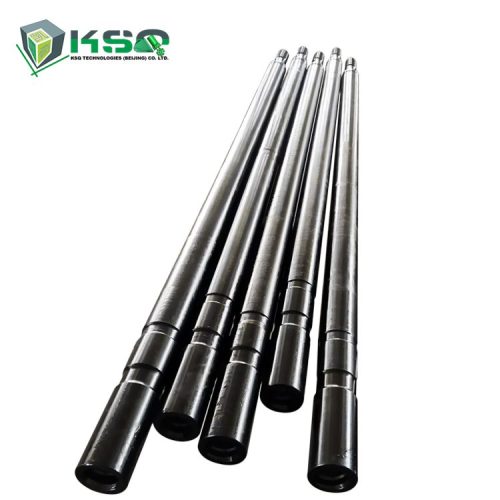

Drill Tube & Guide Tube

T38-1525mm Drill tube & Guide Tube for Bench and long-hole drilling

| Material | Alloy steel |

|---|---|

| Processing Type | Forging |

| Application | Mining / Quarrying / quarrying / Construction |

| Advantage | Good quality and lower price. |

| Color | Black or based on customer requirements. |

| MOQ | No MOQ required for testing and trial order |

| Body Type | Round shape |

| Thread type | R32,T38,T45,T51,T-WiZ60 |

| Type | Thread Extention Rod and MF rod |

| Length | 600mm-6400mm |

| Certification | ISO |

Product Description

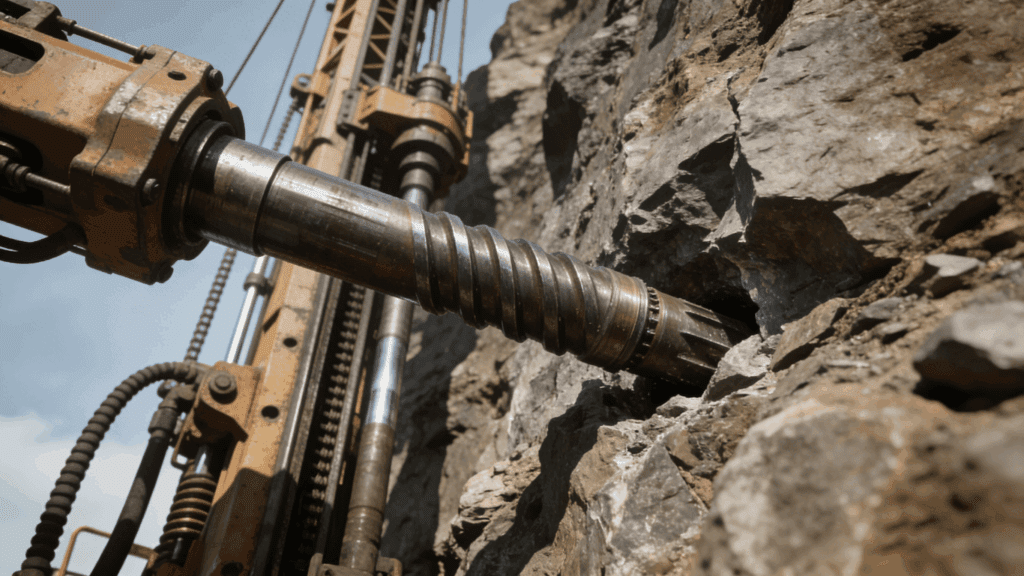

In top hammer drilling, guide tube and drill tube are mainly used for surface bench drilling and underground long hole drilling. the guide tube serves the purpose of guiding the drill bit accurately to the desired drilling location. The drill tube is primarily used to increase drilling tool strength, enhance impact energy transfer, conduct deep hole drilling, or maintain drilling hole stability. especially in challenging geological conditions or when drilling inclined or deviated boreholes. The guide tube ensures precise drilling accuracy and borehole alignment, making it crucial in applications where drilling accuracy is paramount, such as exploration drilling, geotechnical drilling, and construction projects.

We can provideR32guide tube, T38 guide tube, T45 guide tube, T51 guide tube, T-WiZ60 drill tube…

| R32 Guide tubes | ||||||||

| Length | Shank thread | Carburized or surface hardened | Shape | Section | Flushing hole | Coupling D | Wrench flat | |

| mm | foot/inch | mm | mm | mm | ||||

| 1000 | 3’3⅜” | R32 | C | Rnd44 | 44 | 27 | 32 | Yes |

| 1000 | 3.3⅜” | R32 | C | Rnd44 | 44 | 44 | 44 | 44 |

| 1220 | 4′ | R32 | C | Rnd45 | 45 | 10 | 32 | Yes |

| 1220 | 4′ | R32 | C | Rnd45 | 45 | 45 | 45 | 45 |

| 1833 | 6′ | R32 | C | Rnd44 | 44 | 27 | 32 | Yes |

| 1833 | 6′ | R32 | C | Rnd45 | 45 | 10 | 32 | Yes |

| 1830 | 6′ | R32 | C | Rnd44 | 44 | 44 | 44 | 44 |

| 1830 | 6′ | R32 | C | Rnd45 | 45 | 45 | 45 | 45 |

| T38 Guide tubes | ||||||||

| 1220 | 4′ | T38 | C | Rnd56 | 56 | 43 | 64 | Yes |

| 1220 | 4′ | T38 | C | Rnd56 | 56 | 43 | 64 | Yes |

| 1525 | 5′ | T38 | C | Rnd56 | 56 | 43 | 64 | Yes |

| 1830 | 6′ | T38 | C | Rnd56 | 56 | 43 | 64 | Yes |

| 3050 | 10′ | T38 | C | Rnd56 | 56 | 43 | 64 | Yes |

| 3660 | 12′ | T38 | C | Rnd56 | 56 | 43 | 64 | Yes |

| 3660 | 12′ | T38 | C | Rnd64 | 64 | 46 | 46 | Yes |

| T45 Guide tubes | ||||||||

| 1220 | 4′ | T45 | C | Rnd64 | 64 | 46 | 64 | Yes |

| 1525 | 5′ | T45 | C | Rnd64 | 64 | 46 | 64 | Yes |

| 1525 | 5′ | T45 | C | Rnd64 | 64 | 46 | 64 | No |

| 1830 | 6′ | T45 | C | Rnd76 | 76 | 50 | 76 | Yes |

| 1830 | 6′ | T45 | C | Rnd64 | 64 | 46 | 64 | Yes |

| 1830 | 6′ | T45 | C | Rnd64 | 64 | 46 | 64 | No |

| 1830 | 6′ | T45 | C | Rnd64 | 64 | 46 | 64 | Yes |

| 3660 | 12′ | T45 | C | Rnd64 | 64 | 46 | 64 | Yes |

| 3660 | 12′ | T45 | C | Rnd76 | 76 | 50 | 76 | Yes |

| T51 Guide tubes | ||||||||

| 1830 | 6′ | T51 | C | Rnd76 | 76 | 50 | 76 | No |

| 1830 | 6′ | T51 | C | Rnd76 | 76 | 50 | 76 | Yes |

| 3660 | 12′ | T51 | C | Rnd76 | 76 | 50 | 76 | Yes |

| 3660 | 12′ | T51 | C | Rnd76 | 76 | 66 | 76 | Yes |

| 3660 | 12′ | T51 | C | Rnd87 | 87 | 66 | 87 | Yes |

| T-WiZ60 Guide tubes | ||||||||

| 1830 | 6′ | T-WiZ60 | C | Rnd76 | 76 | 226 | 76 | No |

| 3630 | 11.10⅞” | T-WiZ60 | C | Rnd87 | 87 | 226 | 87 | No |

| 4240 | 13.10⅞” | T-WiZ60 | C | Rnd87 | 87 | 226 | 87 | No |

| 4240 | 13.10⅞” | T-WiZ60 | C | Rnd76 | 76 | 226 | 76 | No |

| 4240 | 13.10⅞” | T-WiZ60 | C | Rnd87 | 87 | 226 | 87 | No |

| 6065 | 19.10¾” | T-WiZ60 | C | Rnd87 | 87 | 226 | 87 | No |

For top hammer drilling, drill tubes are generally applied in the following scenarios:

Reinforcing the Drilling System: Drill tubes are often employed when there’s a need to reinforce the drilling system to handle harder rock formations or challenging drilling conditions. By using drill tubes, the overall strength and stability of the drilling system can be enhanced, reducing vibration and wear on the drilling components.

Increasing Energy Transfer: Drill tubes can facilitate better energy transfer from the hammer to the drill bit. This is particularly useful when drilling through dense or abrasive rock formations where maximizing impact energy is crucial for efficient drilling performance.

Deep Hole Drilling: For drilling deeper boreholes, longer drill strings are required. Drill tubes allow for the assembly of longer drilling strings by connecting multiple tubes together, enabling the drilling operation to reach greater depths.

Maintaining Drilling Stability: In unstable or fractured rock formations, drill tubes can help maintain drilling stability by providing additional support and reducing the risk of deviation or hole collapse during drilling.

Competitive Advantage

- Very competitive price

- Professinal service team and special after sale team

- Fast response about all questions from clients

- Design based on your specific requirements

Get a quote

Frequently Asked Questions

Q:Are you manufacturery or trade company?

A:We are manufacturer, has more than 10 years of professional production experience .Products including DTH Hammer and Bit、Drill Pipe Casing System、Tricone Bit、Top Hammer Drill Rod、 Drill Bit、Tapper Button Bit and Rod、 Integral Drill Rod etc.

Q: Do you offer warranty on your products?

A: Yes. For different products we offer different warranty that cover all manufacturing defects in materials and workmanship. The longest period of warranty is 6 months after shipping date.

Q: How is your quality control?

A: We have our own experienced quality control. There will be strict inspection and testing for every order before shipping out.

Q: How long is your delivery time?

A: 1-5days for the products in stock; regular order delivery in 2-3weeks.

Q: After Services

A:(1) Our sales team will response for your question within 24 hours (Holidays included).

(2) Technical Support will be available in any time.

(3)Free replacement will provide once the failure confirmed caused by our product quality.

Q:Methods of Payment

A:We offer different payment terms, including T/T, D/A, D/P, L/C and O/A, etc. You can choose your preferred payment methods before we shipping the goods.

Q: Do you offer OEM service?

A:Yes, we can offer OEM service if you have regular requirement.

Q: Where did you export ?

A:Till 2022 we have exported to 50+ countries.

Product Categories

Top hammer drilling tools

Down-the-hole Drilling Tools

Self-Drilling Anchor System

Rotary Drilling Tools

Diamond exploration Drilling Tools

Tapered drilling tools

Product

Professional rock drilling tool manufacturer