Home » Drill Solutions » Self-Drilling Anchor System » What is a Self Drilling Anchor Bolts? What are the differences?

What is a Self Drilling Anchor Bolts? What are the differences?

Follow-pipe drilling is a common method used to support fractured strata. In recent years, Self Drilling Anchor Bolts have become the preferred choice internationally for supporting fractured formations. Compared to traditional follow-pipe drilling, what are the advantages of Self Drilling Anchor Bolts in terms of construction techniques and cost?

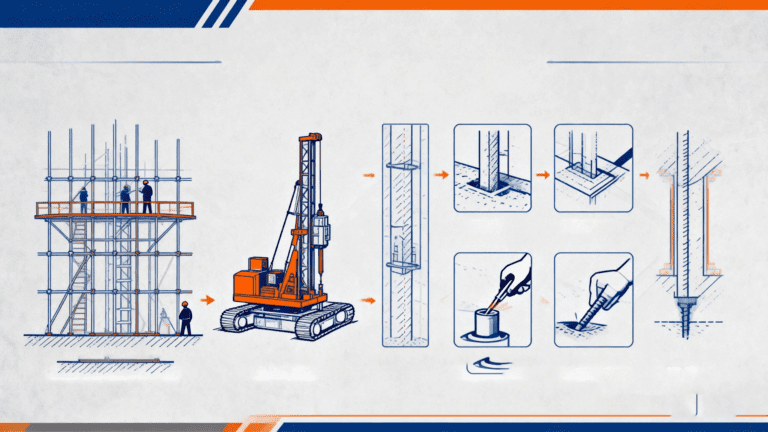

1.Pipe-Following Drilling Construction Process

Pipe-following drilling is mainly used in loose formations or sandy layers to prevent borehole collapse or sand flow blockage during anchor rod installation. The method typically involves either drilling while simultaneously driving the casing into place, or first positioning the casing before drilling the rod. The entire process requires multiple steps and significant manpower coordination.

Construction Process: Erect drilling rig operation scaffolding → Measure hole positioning → Position drilling rig → Install drilling tools and bore hole → Remove cuttings after hole formation → Dismantle drill pipe → Place anchor rod → Extract casing → Grout anchor rod → Acceptance inspection

2.Differences Between Pipe Drilling and Self Drilling Anchor Bolts

1. Drilling Tools Differentiation

Pipe-following drilling requires the use of drilling rigs, drill strings, drill pipes, casing, and pipe boots. Regularly inspect the external condition of drill strings; if cracks or other abnormalities are detected, replace them to prevent drilling stoppages caused by breakage. Self Drilling Anchor Bolts, when paired with drill bits and connecting sleeves, can perform both drilling and grouting functions.

2. Differences in the Construction Process

Pipe-assisted drilling construction involves slow hole formation through complex processes such as light pressing, gradual drilling, and repeated flushing. If stuck drill situations occur, construction time can increase exponentially. Self Drilling Anchor Bolts function as drill rods themselves, eliminating the need for casing construction. The rock bolt can be directly connected to the drill bit for drilling.

3. Differences in Construction Costs

After pipe drilling, the drill string and casing must be withdrawn slowly. Excessive force can damage the drill bit and pipe boots. Material costs are around 100 RMB per meter, with labor costs (due to the manpower required) at approximately 30 RMB per meter. The combined material and labor cost for Self Drilling Anchor Bolts is about 70 RMB per meter.

Overall, Self Drilling Anchor Bolts can replace casing-assisted drilling in most scenarios involving fractured rock formations, offering advantages in both construction techniques and labor costs. In modern support construction projects, achieving superior construction quality and higher efficiency is our shared goal. For detailed information on self-drilling rock bolts, contact KSQ Drill.